Manufacturing shipbuilding parts demands extremely high processing reliability and resistance to environmental corrosion. Workpieces are typically large and heavy, making it challenging to guarantee positioning accuracy. The solution involves using specialized fixtures and CNC rotary worktables to enhance clamping efficiency and precision. This ensures the precise assembly requirements for critical ship systems like power trains and propulsion units are met.

Yes, they can be extensively customized. Based on your workpiece requirements, you can configure the machine with various standard or custom attachment heads, different milling or boring worktables, and a wide array of tool magazines, including libraries for both tools and attachment heads.

Clearly define its intended use. For CNC machining operations requiring high productivity, a more powerful spindle with higher speed and torque specifications is necessary. If primarily used on horizontal surfaces, a spindle with a greater depth of cut might be preferable.

These machines offer high rigidity and precision. The bed, spindle, and tool system are designed to be compact, providing excellent rigidity and minimizing vibrations during processing. The high-precision spindle system maintains stability at high speeds, ensuring accurate dimensions and surface quality. Furthermore, the CNC system's built-in tool compensation function can reduce errors caused by tool wear, thereby enhancing machining accuracy.

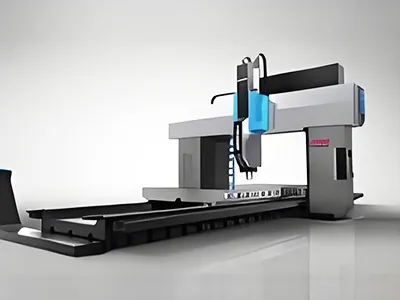

Besides traditional boring and milling functions, CNC planer type boring and milling machines can also perform planing operations, making them suitable for multi-sided and large-area machining. The worktable of a CNC planer type boring and milling machine is typically larger, capable of handling heavier workpieces, and thus suitable for heavy machinery component processing.

Shipbuilding involves processing extra-long and heavy components. CNC planer type boring and milling machines, with their long travel and high stability, can machine large-sized, heavy parts. These machines also offer multiple functions like milling, planing, and boring, enabling the processing of complex-shaped parts, reducing machining steps, and improving production efficiency.

Traditional milling utilizes a boring bar for machining, while modern milling often employs a ram (without a boring spindle) structure to accomplish various functional attachments.

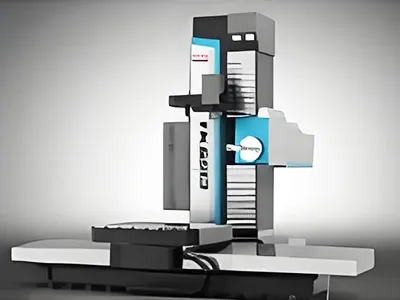

It features machining functions such as boring, drilling, milling, and slotting. Equipped with a high-precision rotary table and right-angle milling and other functional attachments, it can achieve five-sided machining.

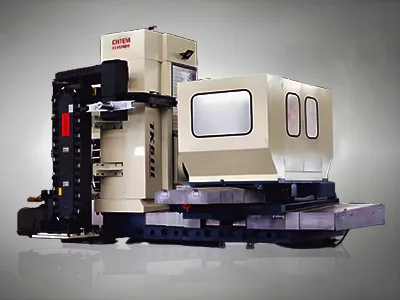

Its structural characteristic is a machine bed cast from iron material, capable of supporting workpieces weighing several tons. Additionally, the planer type boring and milling machine is equipped with a boring and milling head and a rotor, enabling multi-angle and multi-directional machining of workpieces. Compared to ordinary machine tools, its speed and feed rates have been significantly improved, allowing for milling that can achieve a mirror-like surface finish on hardened materials without the need for grinding. Furthermore, it can perform various machining methods such as drilling and milling, with higher machining accuracy and surface quality than ordinary machine tools.

The main structural components of a CNC gantry machining center can be roughly divided into seven parts:

Gantry machining centers machining large workpieces are prone to vibration. The heavier the gantry machining center, the thicker the foundation should be. The low-pressure strength of the concrete should be 1800 N per square meter, and the tensile strength should be 180 N per square meter. The bearing capacity of the ground should be greater than 5 tons per square meter. The concrete foundation must be free of cracks. Vibration damping materials should be added to the foundation workshop.