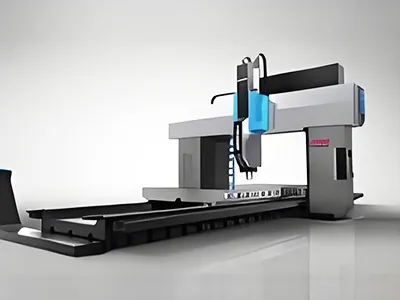

Boring and milling machines have numerous important applications in both upstream and downstream processes related to forging technology. All critical components of forging equipment, due to their material properties and dimensions, rely on the precise machining capabilities of boring and milling machines for their manufacturing.

Examples include machining die cavities and hole systems for forging dies, as well as the main bodies, worktables, and transmission components of forging equipment.

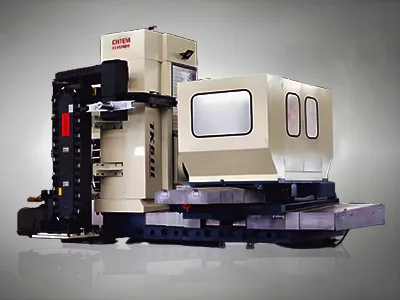

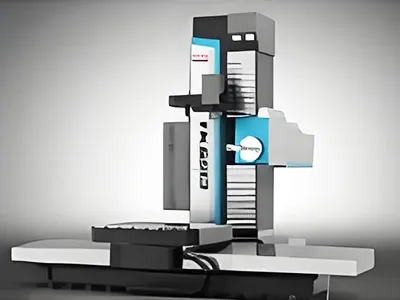

With two decades of dedicated experience in the research, development, and manufacturing of boring and milling machines, CHTEM can provide customized machine tool solutions tailored to the specific machining characteristics and dimensions of Forging Equipment manufacturing.

Our boring and milling machines can achieve micron-level and even higher precision machining, ensuring that the dimensional accuracy, shape accuracy, and surface roughness of these critical components meet stringent requirements.

We offer a diverse range of equipment with various functions and sizes to meet the processing and production needs of different machine models and components.